(Click here to view pt. 1 of this transmission rebuild)

How long it takes for an engine or transmission to require an overhaul depends on a lot of factors. Operators who perform regular maintenance and work in non-harsh environments are going to get a much longer life out of their heavy equipment components than operators who skip basic maintenance and work in a jungle or arctic tundra. Still, no matter how well you take care of your machine and its components, you will eventually need to address critical maintenance issues and updates to keep it running efficiently.

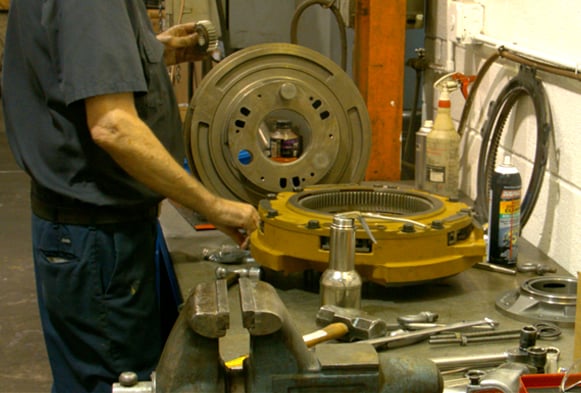

At ACTParts, our rebuild department specializes in analyzing and identifying the parts inside of a component that are preventing it from working at full efficiency. Addressing these not only enables the component to work properly, it helps prevent other critical component parts from becoming worn or failing prematurely and, eventually, causing more problems and downtime.

The transmission being rebuilt in the video below was updated to include all major engineering updates. As long as its end user makes regular maintenance a high priority, such as replacing filters, they can expect thousands of hours of use out of their component before having to worry about another overhaul.

In our next video, we will be finishing the rebuild of this transmission and moving it to the dynamometer (dyno bench) so that we can be sure our customer is receiving a quality-tested product which we stand behind.